With their ability to use media over and over again, regenerative filters are considered the wave of the future.

As director of maintenance at Mt. Olympus, Jason Hammond's job is to prevent Poseidon's Rage from spreading Cryptosporidium's Revenge. That's why Hammond relies on four regenerative media filters to keep the pool's 1.5 million gallons of water sparkling and safe. The filters, which employ a milled mineral called perlite as the filter medium, represent a departure for Mt. Olympus, which features sand filters on all of its other water attractions. However, sand filtration on a pool the size of Poseidon's Rage would be impractical, according to Hammond. "We'd have to use between 50,000 and 60,000 gallons of water a day to backwash high-rate sand filters on a 1.5 million-gallon pool," he says. "With the regenerative filters, we only use 5,000 gallons of water every two weeks."

And because water that goes down the drain carries with it all the heat and chemicals used to prepare it for public use, those too must be replaced. "There's no product in the industry right now, worldwide, that has the potential benefits of this filter, whether it's ours or anybody else's," says Barry Gertz, president of Coventry, R.I.-based Neptune-Benson, which supplied the filters for Poseidon's Rage. "It all stems from the fact that this filter eliminates about 90 percent of the wastewater associated with sand filters - hundreds of millions of gallons of water a year."

Within that compact footprint are housed several hundred to several thousand finger-like flex tubes - stainless steel coils covered in a polyester braid mesh - that hang down from a tube sheet to serve as the filter septa. The filter media is drawn from 25- or 50-pound bags through a hose and into the filter tank using a built-in vacuum-transfer system. When water pressure is introduced to the tank, the powder coats the tubes and grabs hold of contaminants as pool water circulates through at flow rates that may range from 85 to 2,800 gallons per minute. Because the filters operate primarily on the premise of surface-area filtration, as opposed to the depth filtration required of sand filters, pumps don't need to work as hard to maintain desired flow rates.

"That translates into pumping efficiency with respect to the electrical requirements of the pump," says Ken Bergstrom, president of Wayne, N.J.-based Filtrex, which introduced regenerative filtration to the U.S. recreational aquatics market some 37 years ago (it had been used previously in industrial applications). Says Gertz, "Whereas a 25-horsepower pump might be necessary on a sand filter, we get away with a 20-horsepower pump. A sand filter is typically designed to handle 15 gallons of water a minute through every square foot of filter area. With our filter, it's about 1.2 to 1.5. It's going through at one-tenth the speed." And, Gertz adds, water in a regenerative filter is exposed to roughly 10 times the amount of media surface area as in a sand filter.

Where does the "regenerative" part come in? To expose the maximum amount of surface area of the chosen media - be it perlite or D.E. - the filters go through periodic "bump" modes, during which the water pressure is shut off and the dirty media is mechanically shaken off the septa tubes and into the bottom of the tank, where it is broken down and stirred up. When pressure is reintroduced via a closed loop that temporarily bypasses the pool's recirculation system, the same media, as well as the particulate matter it has captured so far, is forced to reattach to the septa tubes in an entirely different configuration as before. This is what differentiates regenerative filters from other precoat filters, which use the same media types, but in only one manual application at a time before the media becomes saturated with debris and requires replacement. (Turning the pump off and back on again will cause the media in these so-called static cake filters to drop and then reapply, but not necessarily in an even coat.) "The key is exposing new surface area," Bergstrom says. "We can use 90 to 95 percent of the total dirt-holding capacity of the media, as opposed to just the outer 10 percent."

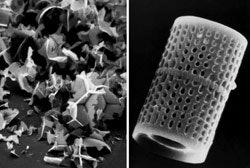

The natural dirt-holding capacity of the types of microscopic media used in regenerative filters deserves a closer look. Research presented last October at the World Aquatic HealthTM Conference in Cincinnati reveals that both D.E. and perlite, when tested repeatedly under ideal precoat filtration conditions, remove on average more than 99 percent of elusive and potentially deadly Cryptosporidium oocysts in a single pass. To be exact, perlite removed 99.941 percent on average; a residential-grade D.E. removed 99.549 percent (an update to the study completed this year used a finer commercial-grade D.E. and achieved an average 99.995 crypto-capture success rate). Meanwhile, sand filtration, still the most widely used method of recreational water treatment, removed 31.3 percent of crypto on average. Adding a maintenance-level dose of clarifier (a liquid polymer that helps small particles bond together for easier removal) improved sand's performance, but the enhanced filtration conditions still only reached a crypto-capture success rate of 61.1 percent. More comprehensive testing with pool clarifier products is being planned for the near future, according to University of North Carolina at Charlotte engineering professor James Amburgey, who conducted the tests.

Amburgey's expertise in drinking water treatment has urgent relevance to recreational aquatics, according to Kim Walsh, director of marketing for filtration at EP Minerals, which funded the media study. Walsh points to a report released by the U.S. Environmental Protection Agency mere weeks after the WAHC in October stating that recreational swimmers ingest an average 32 milliliters of pool water per hour, with children swallowing 47 ml hourly on average. "The CDC believes that ingesting as few as 10 Cryptosporidium oocysts can cause infection in 50 percent of the population," Walsh says. "It only takes 0.14 grams of fecal mater to release a hundred million oocysts. You can't see that in the pool. You don't have visible evidence that you have an outbreak. The recreational water market was saying, 'Hey, we're not dealing with drinking water, so our filters are going to be different.' That's why we did this research."

In fact, D.E., which has left some recreational pool operators wary of its reputation as a carcinogen, is used widely and safely to filter beverages of all kinds - from drinking water to fruit juice. "If you've ever drank cold-filtered beer in your life," says Bergstrom, "the beer probably came through D.E."

Bergstrom, whose company stopped selling sand filters in the early 1970s, estimates that perhaps only five percent of recreational water is currently treated using regenerative filtration. But given the fact that Filtrex's business doubled in the past year alone, he expects that number to expand rapidly in the near future.

Like many theme parks, Hersheypark in Hershey, Pa., features water-themed rides that patrons experience in their street clothes. But the opening last year of The Boardwalk, a cluster of five water-play features that includes one billed as the largest in the world, required a reexamination of filtration. "We've actually used sand filtration with some of our existing amusement rides, but once we started submerging people in water we wanted to go to what we felt was the next level," says Hersheypark senior director of maintenance Gary Chubb, who oversees The Boardwalk's Filtrex system. "The clarity of the water is superb, and the system is easy to use. We did use a little bit more D.E. filter media than we originally had planned to, but that was because our bather load was probably one-and-a-half to two times what we anticipated."

"I think the real driver here is water quality," says Scot Hunsaker, president of St. Louis, Mo.-based aquatics consultancy Counsilman-Hunsaker. "Because we're seeing the pools become shallower, with less volume, and the usage go through the roof, we're having to do a better job of mechanically removing particulates from the water. We can do it with sand, but it takes more sand filters and lowering the flow rates and using polymers. We can trick out these filters to try to do the best we can, or we can look at a different filter medium that does it by its very nature."

Just as pools and water parks are getting more crowded, so too is the North American regenerative filter market. In February, Nemato Corp. of Whitney, Ont., through a licensing agreement with the Atlas Filter Company of South Africa, released a filter that employs rigid, more widely spaced septa, fiberglass components and a hydraulic pulse regeneration cycle that (similar to a traditional backwash, but without the water loss) dislodges the media by reversing flow through the septa as opposed to physically bumping them - all of which simplifies operation while stretching six filter runs across a calendar year, according to Nemato president Steve Andrews.

Flushing D.E. down the drain can be a bit tricky. Since it doesn't decompose (it's already millions of years old), local ordinances may require that used D.E. be strained, bagged and disposed of. And then there are the perceived health risks to the D.E. handler brought on by airborne crystalline silica. "There has never been a single case of cancer or death attributed to D.E. in the aquatics industry, and we've been using it since 1943," says Bergstrom, who adds that a filter serving a heavy bather load may require 100 pounds of D.E. to start, four to six regenerations a day and complete media replacement once a month. "I'm not going to try to scare off an operator from using D.E. - to take a one-in-three-trillion chance that he might get a whiff of D.E. and have it cause some lung problems, and trade that for the health of the bathers in the pool. You're still going to need sanitization and good operator training, but D.E. can provide a significant additional layer of protection for the health of the bathing public."

"We felt that the positives outweighed the negatives," says Hersheypark's Grubb. "We handle hazardous materials in other areas, as well, so it's just one more thing for which we have to follow the proper procedures."

Even perlite is classified as a nuisance dust, and EP Minerals' packaging recommends wearing a dust mask when working with either perlite or D.E. Says Walsh, "To put it in perspective, you are exposed to as much crystalline silica in the air at the beach on a windy day as you are when handling D.E."

Because Mt. Olympus stands to save an estimated $13,261 annually by running 60-horsepower pumps instead of 75s on Poseidon's Rage, the park earned a one-time $7,956 Focus on Energy grant from Alliant Energy, which serves Iowa, Minnesota and Wisconsin. Says Gertz, "A good number of projects that we've worked on so far have been interested in LEED certification, and our filters have really helped them get a lot of points."

As with any maturing technology, even initial investment costs are poised to come down. "It's happening as we speak," Gertz says. "We used to have 30 different models. Now we're down to five. Our repeatability in manufacturing is bringing these prices down, and we expect that to continue."

Not surprisingly, those supplying the recreational aquatics market with regenerative filters and media see regenerative media filtration as the industry's future. "I believe it is," says EP Minerals' Walsh. "Neptune-Benson believes it is. Filtrex believes it is."

Others do, too. "I think regenerative media filtration is going to continue to be a sought-after solution for improving water quality and minimizing operating costs," Hunsaker says. "And I think we're still seeing the first generations of this. We're going to continue to see this technology refined. We're going to see costs come down and performance go up."