The simple mixture of cement, water and aggregate remains a key building block in modern sports facilities

Expectations are running high right now at the Georgia Institute of Technology, where the first phase of a major renovation project enclosing the university's outdoor Olympic Aquatic Center - site of the 1996 Summer Games' swimming and diving events - edges toward completion. Not only will the project convert the center into a year-round facility for students and world-class athletes alike, it will also add one floor above the pool for six basketball courts, an auxiliary gym, a suspended jogging track and multipurpose rooms. Integral to the project are several poured-in-place concrete beams, each measuring 13 feet deep and spanning the natatorium's 176-foot-long ceiling - the longest such span in the United States, project officials say.

Meanwhile, across the country in Layton, Utah, the 35,000-square-foot gymnasium at Central Davis Junior High School has become a local architectural landmark, thanks to six basketball-shaped, pecan-colored concrete panels erected along the exterior facade. Created using tilt-up concrete - an on-site process of casting the concrete on the ground and then literally tilting it into place - each panel was sandblasted to create a pebble-grain texture similar to the surface of a basketball, minimizing wall scale and adding character to an otherwise boxy facility.

Georgia Tech and Central Davis Junior High are just two recent illustrations, more than 2,000 years after its introduction, of the versatility of concrete. "Concrete is like plastic," says Bennet Stindt, an associate principal and senior designer at HOK Sport+Venue+Event in Kansas City, Mo. "It's easy to form and manipulate. We can do just about anything with it."

Facility owners typically don't get directly involved in choosing what kind of concrete will be used for structural and aesthetic purposes; that's a task best left to architects and engineers. Says Erik Kocher, a principal and owner at Hastings & Chivetta Architects in St. Louis, "There are just too many variables involved." But possessing knowledge of the different kinds of concrete, their applications and the myriad finishing options available will give facility owners an edge when it comes to discussing the structural integrity and exterior appearance of their buildings.

In any discussion of concrete, it's important to first distinguish the difference between the terms "cement" (an ultra-fine gray powder) and "concrete" (the hardened result of blending cement and water with sand, gravel or other aggregate). Quite simply, concrete would not exist without cement.

The history of concrete, according to some scholars, dates back 12 million years. They believe that when the earth was undergoing intense geological changes, natural cement was actually being created through the interaction of limestone and oil shale.

Early Assyrians and Babylonians used clay to bind stones together and build structures, while early Egyptians used limestone and gypsum mortar to form pyramids. In a precursor to modern concrete, Ancient Romans created a primitive mix of small gravel, coarse sand and water to complement arches and vaults, covering spaces far larger and with far greater flexibility than had been possible before. They also used concrete to build aqueducts and thousands of miles of road.

In 1824, British bricklayer Joseph Aspdin created what concrete experts claim was the first true artificial cement, dubbed Portland cement because its color resembled that of stone quarried on the British Coast's Isle of Portland. Aspdin burned limestone and clay together and ground the mixture, changing the chemical properties of the materials and creating stronger cement than previously produced by crushed limestone and clay. By the mid-1800s, concrete reinforced with embedded steel was in wide use, offering both the tensile strength of metal and the compression strength of concrete.

Today, Portland cement, also known as hydraulic cement, comprises about 98 percent of all cement produced in the United States and consists of a predetermined chemical combination of calcium, iron, silicon and aluminum. Concrete, meanwhile, is the most widely used building material in the world, and it comes in many forms, shapes and sizes. Annual global production hovers around 5 billion cubic yards, or about 1.25 billion tons.

That said, certain concrete works better for some facilities than others. For example, precast panels - concrete walls mixed, poured and formed offsite, trucked to the job site, erected and affixed to steel frames using crane operators and steel workers - are most commonly used in everything from college recreation center exteriors and interiors to stadium and arena seating bowls. Concrete masonry units (CMUs) - blocks, in essence - are just as popular but are installed like bricks by masons. Both types of concrete are often treated with special finishes to enhance the look of traditional gray concrete.

Because concrete is so versatile, many of its forms - from precast and block to tilt-up and poured-in-place - can be incorporated into athletic, fitness and recreation facilities depending on design and budget demands. Here's a primer on the most popular options.

• Concrete masonry units. "The mainstay of the business," as one architect puts it, CMUs are available with flat or bull-nosed sides and edges, curved corners and other design elements. The finished appearance of an interior or exterior CMU wall supported with rebar - reinforcing steel bars held in place within the blocks' interior cells by grout - varies depending on each unit's size, shape and color, as well as the chosen mortar, bond pattern and surface finish.

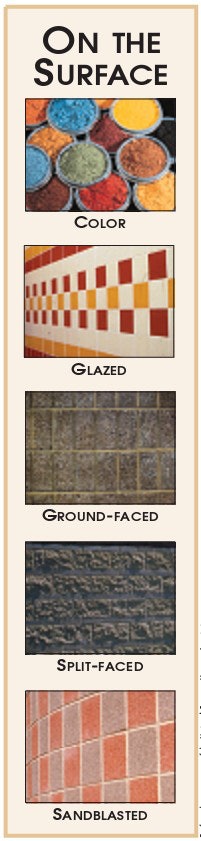

Color is the single biggest variable in the appearance of concrete masonry. As with other surfaces, paint or stain can be applied to CMUs, although stained treatments are more popular because the price is only slightly higher than paint. Also, stains lend the block a pleasing stony or earthy appearance.

Pigmented concrete takes staining a step further by introducing color within the entire cross-section of the block. CMUs are colored by adding mineral-oxide pigments to the concrete mix. Mortar can also be colored to blend or contrast with the blocks. While colors used to be limited primarily to earth tones, brighter shades such as blues and yellows are now available but may cost more if they require white cement. The final unit color depends on the amount and type of pigment used, the cement and aggregate color, and the amount of water in the mix - a wetter mix will generally produce lighter and brighter colors.

When all CMUs must be exactly the same color to achieve a particular architectural effect, the National Concrete Masonry Association (NCMA) in Herndon, Va., recommends that uncolored units be used, then painted or stained the desired color.

More costly surface alternatives include split-faced units, produced by molding two CMU blocks face to face, then mechanically splitting them after curing, thus creating a fractured surface that boasts a natural stone-like texture and discourages graffiti. Ground-faced (or burnished or honed) blocks are polished to achieve a smooth finish, revealing natural aggregate colors. Glazed blocks are produced by bonding a colored facing (typically made of polyester resins, silica sand and chemicals) to a CMU for a smooth and impervious surface, while sandblasted units create the opposite effect by exposing the aggregate for a rough and weathered appearance.

CMUs with various surface treatments are often used throughout both the exteriors and interiors of all types of facilities. Glazed blocks work well in concessions areas, rest rooms and aquatic spaces. (High-traffic areas should also be treated with an epoxy sealant to guard against graffiti, skid marks from shoes and balls, and other potential markings.) Meanwhile, colored and textured treatments brighten up offices, locker rooms and multifunctional areas.

In some cases, CMUs serve as both the interior and exterior wall, increasing the potential economic and aesthetic advantages. While the NCMA touts that type of dual-purpose structure as a cost-saving measure, it's not an application eagerly embraced by sports-facility architects. Such walls often don't contain insulation and have no water or air cavities, according to Kocher. "If that wall cracks," he says, "you can literally see daylight." Kocher and other architects recommend (budget permitting) erecting a four-inch-thick wall using bricks, precast panels or more CMUs on the exterior side as a "skin," and then installing sheets of rigid foam insulation between the skin and the interior CMU wall.

• Precast concrete. Precast concrete panels allow for as much freedom of design as block, and offer just as many finish options. They're also now easier than ever to use - thanks to technological advances that allow engineers to calculate exactly how much steel-reinforcement tonnage a precast concrete facility will require. Such information was not available decades ago, so designers erred on the side of caution and overcompensated by building stadiums and other structures characterized by hulking masses of concrete. Today's facilities are more elegant and less monolithic than their predecessors because today's precast concrete panels are usually only three or four inches thick.

Like CMU structures, rigid foam insulation can be sandwiched between interior and exterior precast panels, which are welded or bolted to a structure's steel frame. A facility's height is not an issue (as it is with tilt-up concrete, due to control issues during installation), although individual precast panels are usually no taller than eight feet for freight purposes.

Stone or brick veneers can be applied with mortar to precast concrete after it is set in place. The street side of the Fulton & Susie Collins Fitness Center at the University of Tulsa, for example, uses tan sandstone and white limestone on precast panels to blend with other campus buildings. The back of the facility, however, employs unadorned - and thus more cost-effective - precast panels.

Virginia Polytechnic Institute and State University's Lane Stadium - the majority of which boasts concrete construction circa the height of the post-modern architecture period of the 1950s and 1960s - offers an example of how surface-treated precast panels can be combined with other forms of concrete to create an appealing aesthetic. Recently renovated concrete towers featuring spectator walkways consist of CMU bases covered with locally quarried limestone mortared to the blocks. Sandblasted tan precast panels then extend up the towers, creating a sharp visual contrast between surface finishes.

Another advantage of using precast concrete in regions with colder climates is that panels can be manufactured in a factory during the winter months and then shipped to a job site when the weather improves - an option that, in particular, aids the completion of fast-track projects.

• Poured-in-place concrete. A poured-in-place concrete wall is one in which the concrete is poured onsite using portable forms to shape it around rebar and between the building's steel framework. Decades ago, many stadium and arena seating bowls consisted of poured-in-place concrete. That's still the case in some parts of the country where labor costs are low or where a construction site is located on a berm with a built-in natural bowl that serves as the structural framework. More likely, however, most bowls today are formed using precast slabs and steel frames.

Likewise, little poured-in-place concrete is used for other athletic, fitness and recreation facilities - save for floors and long-span structures such as the one at Georgia Tech's Olympic Aquatic Center. Rather, depending on a building's configuration, CMU, precast concrete or steel-frame structures are more popular. "There is a greater opportunity for human error using poured-in-place concrete. Precast concrete is prepared in a controlled environment," says David Body, a principal with Cannon Design in Los Angeles.

• Tilt-up concrete. The same concerns about unpredictability can also translate to tilt-up concrete. Often compared to poured-in-place concrete because the material is prepared at the job site, tilt-up concrete is considered similar to precast panels, as well, because of the manner in which it is erected.

When casting tilt-up concrete (usually done on the facility's floor slab), rebar is built into the concrete, which requires a large and flat ground surface on which to be cast. Lumber is the most common material used for side forms, so the concrete panel depth is usually designed to fit the depth of standard lumber, typically allowing for 5 1/2 and 7 1/4 -inch-thick structural panels. The form sides can be supported and secured to the slab by a wood or steel angle support. They are erected with cranes and set in place using braces five to seven days later.

Tilt-up walls are load-bearing but are often installed without insulation - although the Mt. Vernon, Iowa-based Tilt-Up Concrete Association (TCA) reports that insulated panels are quickly becoming more prevalent in new construction.

Finish options include paint, sandblasting, and brick and stone facing. "Tilt-up is making strong inroads into building types where few were seen only a few years ago," says Ed Sauter, executive director of the TCA.

Those inroads, however, are less traveled by athletic, fitness and recreation facility designers, who tend to equate tilt-up concrete walls with strip malls and industrial buildings. Also, although tilt-up may cost less than other options, as a rule it is not used for structures with a wall height taller than 45 or 50 feet - eliminating most facilities except multipurpose indoor fields, ice rinks, gymnasiums and some fitness centers.

That said, a notable exception to the perceived height rule is the major role tilt-up concrete played in the recent renovation of Jade Stadium in Christchurch, New Zealand. Tilt-up walls measuring as high as 115 feet were the most cost-effective solution for adding 14,000 seats. Crews retained the concrete surface of the walls but added radial shapes, seating buttresses and supporting walls. For the ingenuity of its designers, Jade Stadium won a "Best in Class" distinction in the TCA's 2003 Tilt-up Achievement Awards - the only athletic facility to do so.

Despite the abundance of concrete options, not all are available in all regions of the country - and even if they are, contractors might disagree on which option will cost less. Body recalls one project that was specified for concrete block, but the job's contractor claimed the facility could be built to have the same appearance but for less money using a steel frame. "Sometimes, it just comes down to what the chosen contractor is good at," Body says.

In California, stucco-covered CMUs are often the building materials of choice, while bricks and blocks are readily available for a fair price in the Midwest. In the Northeast, steel remains a construction constant. "Materials for sports buildings tend to be selected on the basis of cost and regional preferences rather than on true function," Body says. But depending on desired sizes and finish treatments, some precast concrete will not be available locally. Kocher says one recent project in Missouri required concrete materials to be trucked in from Arkansas, Indiana, Oklahoma and Texas.

Technological advances in concrete, however, don't adhere to regional boundaries. That's why sound-absorbing concrete has become a popular design component inside facilities where control of acoustics is a priority. Masonry blocks filled with glass-fiber insulation absorb sound and cut down on the reverberation noise caused by hard reflective surfaces such as water, glass, wood, metal and traditional concrete.

Among the latest innovations to emerge are CMUs with angled slots that trap sound waves as they enter the blocks and scatter unabsorbed sound in different directions to diminish echoes and overall noise levels. The cell's slots are skewed to add an additional element of visual interest. Fiberglass insulation inside the block provides extra sound absorption, and an interior metal septum increases the unit's ability to control high-frequency noises. These artificial blocks are only slightly more costly than standard CMUs, according to The Proudfoot Co., which distributes Sound Cells ® to qualified contractors in North America.

New concrete research is ongoing, as scientists and engineers pursue new ways to improve a timeless material. The Concrete Technology Laboratory at Michigan State University, for example, is working on developing new concrete materials and systems with improved performance and durability for infrastructure applications by using recycled materials and wood fibers in concrete.

While technology may be ushering in new ways in which concrete can be applied and treated, concrete still achieves the same effect it did when the Egyptians erected pyramids, when the Romans constructed aqueducts - and, for that matter, when the Americans built the Rose Bowl.

Currently, a team of HOK architects is involved in developing a $500 million preservation and renovation plan for the 81-year-old stadium, one of the few sports venues on the National Register of Historic Places. With the hopes of attracting an NFL team back to the Pasadena, Calif., facility, project coordinators have proposed reducing capacity of the 92,000-seat stadium by one-third, adding suites for corporate customers, building underground parking and expanding the facility from about 400,000 square feet to 1,000,000 square feet. The field level would be excavated to accommodate rest rooms, a concessions concourse and other amenities.

Possible concrete treatments for the Rose Bowl, according to Stindt, whose firm has been retained to conduct a feasibility study of the stadium, include CMUs, precast and poured-in-place concrete that could combine with glass and wood to tie in with the stadium's residential setting. Finishing treatments may include dying the concrete a light patina and borrowing a design technique from the Italians that uses wood to form the concrete, lending it a wood-grain appearance once hardened.

"We're just carrying on what others have been doing for hundreds of years, and that is using concrete to mold and cast beautiful structures," Stindt says. "With concrete, you're getting something that is going to stand the test of time."