This article originally appeared in the April 1978 issue of AB with the headline, “NOCSAE Helmet Tests Are Tougher: Here Are the Steps that Make the Standard Work.”

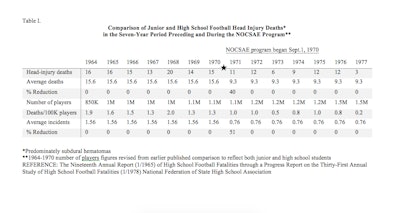

The NOCSAE Football Helmet Impact Standard is helping to reduce serious head injuries as evidenced by the steady decline in head injury fatalities depicted in Table I. Fatalities have declined 51 percent in the seven years that NOCSAE has been influencing helmet design and construction. According to the thirty-first annual study of high school football fatalities by the National Federation of State High School Association, there were only three fatal head injuries in the 1977 high school season which, in terms of comparative statistics, is 0.2 per 100,000 players, the lowest recorded numbers since 1945.

There are a number of causative agents which can contribute to a given head injury, including congenital weaknesses, previous injury, dangerous impact environment or equipment.

Manufacturers have agreed to exchange helmets for testing

To ensure that helmets are doing all they can to maintain or reduce the fatal head injuries in football requires a voluntary nationwide effort devoted to maintaining or improving quality and screening out design weakness or damaged and altered helmets. Some of the specific things being done to make the standard work are as follows:

Round-Robin Tests

In 1977, two round-robin tests were conducted among eight plants including five manufacturers, two National Athletic Equipment Reconditioners Association (NAERA) companies and the NOCSAE lab at Wayne State University. These were done to see how repeatable each test system was operating and how reproducible were results of a helmet test in different plants. A round-robin test between 25 and 30 plants and laboratories, including the major helmet manufacturers and NAERA reconditioners is planned for 1978.

Helmet exchange

All the major manufacturers who are members of NOCSAE have agreed to exchange helmets for the purpose of testing each other’s products.

Manufacturing quality control surveillance

Quality control tests are ongoing in each of the major helmet manufacturers and by the principal investigator NOCSAE.

Reconditioners quality control surveillance

According to the NOCSAE standard, revised September 1977, reconditioning firms who have the NOCSAE test equipment are to conduct a partial NOCSAE standard test on several helmets form each school. In addition, static bench test instruments are being developed to screen greater numbers of helmets. Data from NAERA reconditioning quality control tests is under the surveillance of the NOCSAE principal investigator. Manufacturers and officials of NAERA are meeting together to discuss mutual helmet standards problems.

Facemasks

Several manufacturers and the principal investigator for NOCSAE have conducted independent test with and without several types of facemasks attached to the helmet. The conclusions were that the testing without the facemask, as is presently being done in the NOCSAE standard, is justified not only because of the variety of masks, difficulties with obtaining mask clearance and getting the helmet on and off the model with mask attached to helmet.

Random impact location

Manufacturers and the principal investigator are conducting tests at random locations on representative helmet models to determine if the six impact location specified in the standard can detect all possible weaknesses of the helmet.

Studies planned to determine helmet’s effect on neck injuries

Head model

Three sizes of head models which have humanoid shape, weight and response are presently being used to test helmets. These are the largest sizes in the three common shell sizes used by most equipment manufacturers. The sizes have the least amount of stand-off from the shell and if these sizes pass the NOCSAE standard, it is assumed that the other helmet sizes in that particular shell would also pass. Since most materials offer reduced protection at elevated temperature playing conditions, the standard includes a partial test after exposure to and immediately after a least four hours in a 120-degree F oven. Some consideration is even being given to heat the head model to body temperature.

Severity

At a recent manufacturers Ad Hoc committee meeting to improve the standard, one of the manufacturer’s representatives reported that, based on his years of experience in football as a college player and as a result of recent voluntary tests, he had concluded that the NOCSAE test is very severe. In the voluntary tests he allowed an eight-pound missile to be dropped on his helmeted head in increments up to 42 inches. At this point he felt pain in the neck and bottoming of the shell against his head causing him to stop. He had a stiff neck and headaches for two days. (The NOCSAE standard specifies twelve of the sixteen drop tests at ambient temperature from 60 inches).

Another report which came out of the Ad Hoc meeting indicated that facemask deformations in actual game conditions are similar to the deformations which occur during NOCSAE tests when the mask was left on the helmet.

Tests calibrated against human tolerance

It was also reported at the meeting that the NOCSAE test system is at least as severe as the monorail test system which has been proposed as an alternative to the standard.

It is concluded that the present state of the art of head and neck injury, available materials and construction techniques, and declining head injury fatalities do not warrant changes in the severity of test. With present technology, making the test more severe would result in bigger, heavier, stiffer and more expensive helmets.

Calibration

The NOCSAE test system has been calibrated against human tolerance data, cadaver impact comparisons, electronic and accelerometer shock tests to ensure that the system is calibrated electronically and mechanically as well as the state of the art will permit.

Neck

Basic studies are planned by NOCSAE in the way static and dynamic tests on neck sections and models to determine the effect of the helmet son the mechanics of neck injury and load tolerance of the neck injury and load tolerance of the neck in a variety of loading conditions.

Baseball helmet standards

There are relatively few serious injuries in baseball compared to the large numbers of participants. However, a few deaths and brain injuries are occurring, usually under unknown or controversial circumstances which leave doubt as to whether or not the equipment was at fault. To help remove some of this doubt, the manufacturers are convinced of the need and are cooperating with NOCSAE to develop a standard as soon as possible. There are a large number of variables involved in understanding the mechanics of baseball impacts to the helmeted head. Laboratory research to date indicates that the major reason for the small number of serious head injuries to the helmeted head of baseball players is because of the high probability of a glancing impact when wearing the hard shell helmets.

Hockey helmet standards

NOCSAE has evaluated representative helmets with regard to protection afforded to wearers against falls to a hard, flat surface simulating ice, puck and stick impacts. It has attempted to calibrate its test system to one which has been commonly used in industry to standardize hockey helmet performance. The purpose of these tests is to avoid a proliferation of standards and keep cost down to the manufacturers and ultimately the consumers.