When choosing a wood floor, the grade of wood specified can significantly impact sports-facility aesthetics.

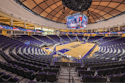

Just as in the residential housing market, wood floors add a certain lustre to a sports facility, whether used in gymnasiums, aerobics studios or racquet courts. But the wood-flooring decision is more complicated than one might anticipate. The grade of wood chosen can make a significant impact on the aesthetics and pricing of the project, and owners and architects are wise to evaluate the differences before making a selection.

The type of wood itself is almost a given today, which simplifies buyers' research on the grading differences. Despite a few scattered applications of oak, ash, beech and other woods, experts agree maple is the industry standard.

But why? "One reason is the lighter color," says Doug Hamar, president of the Maple Flooring Manufacturers Association. "Plus, if you put a piece of maple alongside a piece of oak, you'll find that the grain in the maple is much tighter than it is in the oak. As a result, you have a much lower chance of experiencing things like splintering and splits in the board. Maple has better durability because of its tight grain and density."

Maple is graded according to no one standard (grades of flooring produced by MFMA members are determined by the association). Before the grading process begins, the wood must be manufactured to certain specifications. After the maple is purchased from the sawmill, all major knots, surface defects and structural inadequacies in the wood are cut out. If a knot is 2 feet from the end of an 8-foot piece of flooring, for example, the section including the knot will be removed and the remaining 2-and 6-foot pieces will be set aside for the grading process. The association will not accept pieces shorter than 9 inches, however, so small end sections are usually recycled.

"As we manufacture the flooring, we are defecting out sections that will not meet our specifications," Hamar says. "A furniture manufacturer may need a 2-foot piece to be completely defectfree, and because they can't get that out of a lower grade, the lower grade gets passed along to a flooring mill that can make better use out of it. It allows us to defect lower-grade lumber and wind up with an ultimately highergrade product than a furniture manufacturer might have."

Today, each piece of maple is still hand-inspected during the grading process for two basic distinctions: aesthetics and length. Aesthetically, inspectors must look for character marks and deficiencies. They also measure for length, since a smaller percentage of shorter pieces are allowed for higherquality grades. While it's a time-intensive process, the long production line may be shortened in the future, according to Hamar.

"There is technology that's currently being developed to try to automate that process and make it less labor-intensive," says Hamar. "I won't say it's in its infancy, but it's continually being perfected so that it ultimately will make its way into our industry."

Of the three primary grades of wood, the highest quality is first grade. Generally this grade comes from the growth area of the tree-or the jacket, as manufacturers refer to it. Known for its uniformity in appearance, first grade may encourage the assumption many people make that color is a significant factor in determining the grade. But, Hamar asserts, color does not have an impact on the grading.

gYou can have a defect-free first-grade piece that may be darker than its neighbor simply because of the natural graining of the wood itself," he says. "As long as they're defect-free in terms of knots, splits and cracks, they would both be referred to as first grade. But by default, first-grade material tends to be lighter in color because you don't have the heartwood, knots or mineral streaks."

Specifically, the requirements for first grade require the face of the wood to be practically free of defects. In length, no more than 55 percent of the total footage in any shipment or pallet may be in bundles under 4 feet in length, no more than 25 percent may be in 2-foot bundles and no more than 10 percent may be in 11.4-foot bundles.

"It allows for a very modern, clean and, in some minds, sterile look because it is fairly defect-free," Hamar says. "You don't see dark blemishes or a lot of graining." In the next grade, called "second and better," a little more variation is seen. This grade allows for tight knots and slight imperfections caused by mineral streaks or the graining of the wood itself. According to Hamar, a "wilder grain pattern" can be seen in the second-and-better grade, as well as an increase in the combination of light and dark wood. The wood may be admitted with small aberrations, such as an occasional small, firm pin knot or discolorations and burls that might be removed by sanding the floor when it is laid. For second and better, no more than 60 percent of the total footage may be under 4 feet, no more than 27 percent may be in 2-foot bundles and no more than 15 percent may be in 11.4-foot bundles.

Admittance for third grade is much more accepting of aesthetic flaws in the wood, and since this wood generally comes more from the heart of the tree, mineral streaks and staining are more common. Any knots or defects admitted, however, cannot be damaging to the wood's structural integrity. For example, the grading may admit tight knots or open knots (knots about the size of a pencil that might lead to a slight crack in the surface of the wood). In this grade, no more than 85 percent of the wood may be in bundles of 4 feet or less, and no more than 55 percent may be in bundles under 11.4 feet. Here, there is no specific requirement for bundles in the 2-foot category.

It may be hard to decide which grade to choose based on such minimalsounding differences. Often, however, financial considerations help determine the grade.

"Theoretically, the cleaner the maple, the more expensive it's going to be," says Reed Voorhees, senior designer of sports and recreation facilities for St. Louis-based Jacobs Facilities Inc. "But it comes down to supply and demand. It sort of depends on what's popular and what's not."

For example, Voorhees says, when he was designing the Pointe at Ballwin Commons in Ballwin, Mo. (he was then with Yarger Associates), the decision was made to specify third-grade maple to save money. Because third grade was so popular at the time, however, it actually turned out that second and better was a bit more affordable.

In general, though, prices tend to stay fairly relative to one another. According to Hamar, second and better is generally about 10 to 15 percent less expensive than first grade, and third grade is about 35 to 45 percent less expensive than first grade.

Beyond pricing, the choice often boils down to simple aesthetics. Of course, in those cases in which cost is not a factor, many will choose the first grade simply because it has traditionally been seen as the better floor. But many architects and facility owners have their preferences.

"Those that have chosen third grade have told me they chose third grade because they wanted the warmer look of third grade; they wanted their facility to have a warm, comfortable feel," Hamar says. "Others said they wanted a nice, bright, airy feeling, and as a result wanted to go with the higher-grade product."

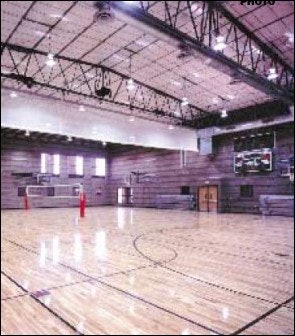

Andy Barnard, vice president and principal for Denver-based Sink Combs Dethlefs, is one architect who will argue for third grade in almost any application. He was the principal in charge of Evans (Colo.) Community Center, which used third grade for its gymnasium flooring. "I like the third grade, especially in a recreation setting," Barnard says. "Cost is one part of it, but it's also nice to get the variation in the wood. It certainly livens up the floor."

The choice also depends to some extent on the application. "For an aerobics room, we typically use secondgrade wood because those rooms tend to be a little smaller," Barnard says. "The amount of color variation that you get on a third grade looks great in a gymnasium setting but doesn't tend to look as good in an aerobics setting." It's a good idea to view photos of similar installations or visit other facilities to see how the wood interacts with a particular setting. Users, too, may have their preferences. Often those are based on perceived notions of performance differences, but there are aesthetic considerations as well.

"In most cases, people will prefer to play on a first-grade floor or a secondand-better floor because it is less distracting," Hamar says. "They're not bothered or confused by grain or color variation in the flooring. Moreover, in lower grades, court lines can become obscured or less visible because of darker or lighter graining of the wood, which can certainly affect their play." Overall, however, performance variation among the three grades is fairly negligible, and all three-even in areas where knots or defects are prevalent-can readily handle the stress from aerobics, basketball or other impact-intensive activity. Any wood not able to handle that strain is rejected early in the process. And while the first grade may generally be more uniform in hardness than the others, even a third-grade floor with its knots and increased variability will have the density characteristics sought in a wood floor.

"All three grades are functionally and structurally sound products," Hamar says. "You will not find that you're going to be compromising the structural integrity of the sports floor by going to, say, third grade vs. first grade." The only potential differentiating factor is shock absorbency, and much of that is due more to the subfloor and supporting system than the wood itself.

While there have not been any conclusive tests to prove that any of the grades have better shock absorbency than the others, some believe a slight advantage exists in favor of third grade. "Theoretically, the shock absorbency value of the third grade should be higher than that of the second and better, which should be higher than the first grade," Hamar says. "The reason for that is that we have shorter pieces of material in third grade than we do in second and better than we do in first grade. Those short pieces are able to flex more than longer pieces are. It's that flexibility that helps determine the shock-absorbing value of a system."

An argument can be made that the reverse is true when it comes to maintenance. Here, the first grade seems to have the upper hand-though again, the difference is fairly negligible. In terms of regular maintenance, the procedures are the same on all wood floors. But first grade may be a little more resistant to climatic changes than lower grades.

"Our experience is that you would find the first grade to be less prone to expansion and shrinkage due to changes in relative humidity than a third-grade product," Hamar says. "The graining in a third-grade product lends itself to be less dimensionally stable than the other grades are."

That said, the decision to go with one grade over another ultimately comes down to cost and aesthetics. "You are really buying aesthetics more than anything else," Hamar says. "It all comes down to consumer preference and what budgets will allow. People should not think they're playing on any less of a floor because they're playing on third grade vs. first or second and better. You could blindfold a person and have them dribble a ball on a first-grade floor, a second-and-better floor and a third-grade floor, and he or she would never know the difference."